|

FEATURED JOBS

|

|

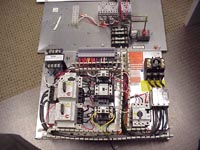

Our featured

job this month involves 3 rotating "total energy" wheel heat recovery

units by Loren Cook we supplied last summer. We recently revisited the

job after a winter of operation. I chose this topic as it ties into

the talk by the recent ASHRAE speaker as far as ducting arrangements

and energy efficiency. See the typical ducting schematics on the attached

photo, which come from the Cook "ERV" catalog, page 4. These typical

ducting arrangements directly apply to the speakers talk as far as feeding

local zone ahu's with a dedicated "outside air" ahu. The speaker seemed

to me to be on the fence about heat recovery in general. I took his

talk to be that heat recovery had its place and application, but was

not needed locally at each air handler. This schematic uses an energy

recovery unit as the "dedicated" outside air machine. Some of you have

personally seen the samples of the standard core material that Cook

supplies. For those of you who have not, you can see the attached photo.

They use a wheel manufactured by Novel Aire Technologies (www.novelaire.com)

which is extremely rugged and has excellent heat transfer characteristics.

You can easily get 75% effectiveness with a wheel sized in its mid range

of face velocity. The Novel Aire

media is a homogenous material, meaning the desiccant is part of the

material, not "coated" or "bonded" onto the material. Some of the other

products out there use a desicant that is sprayed onto the wheel material.

Just the airflow over the wheel erodes the desiccant over time, reducing

the effectiveness of the very heat transfer surface you have paid for. The Novel Air

media is a fluted design. This provides important benefits to an owner.

Besides the superior physical strength of the wheel, it is extremely

flat, and stays flat over time. This means the wheel passes over the

seal between the supply and exhaust air stream and maintains a good

seal. If the wheel is flimsy or is made in sections, the wheel goes

out of "flat" and gaps at the seal. This can result in short circuiting

air between air streams resulting in "missing air" at the grille in

the space. Another benefit

of the fluted design is that the air can only travel straight through

the wheel. With others wheel design, made in pie shaped sections, air

can travel radially. This can result in air short-circuiting from the

supply to the exhaust even if the air flows are balanced. If the airflows

and statics are not balanced, it is almost guaranteed to happen, as

air will always move from high pressure to low pressure. This problem

will manifest itself with missing air at the grille. Consideration

of the defrost cycle is important in our area of the country. The most

common method used that I have seen is the shut off of the supply fan.

This allows the exhaust air to warm up the wheel for a preset time period

after a defrost stat has sensed air below an adjustable setpoint. I have recently dug deeper in how often and when a wheel system will go into defrost. I have found out that in a typical application, where the indoor humidity is 35%, you will not see frosting down to zero degrees. If the RH is 25%, you would be below zero before your defrost cycle would be needed. This gives you a much broader range of operating conditions before defrosting than is commonly assumed. Our units come with the defrost stat set at 30 degrees at the factory. We recommend turning this down to 7-8 degrees to begin with and having the building owner experiment with lower temps gradually. In a typical school, I am guessing you could set it a zero very easily without frosting the wheel. The selection software by Cook is very powerful and easy to use. You can now get updates of their software online, for those of you who do not have the latest disk. That is it. I hope the attached pictures allow you to kick the tires "virtually".

Cook vs. Others |

Ducting Schematics

Wheel Styles

Don't touch this

Hinged Access

Properly Sized Cabinet

Properly Sized Intake

Single Point Power

Stick a fork in it Strong Wheels

Wheel Seal |

Check Out Our Featured Jobs Archive

| Home | | Manufacturers | | Featured Jobs | | Newsletter | | E-mail |